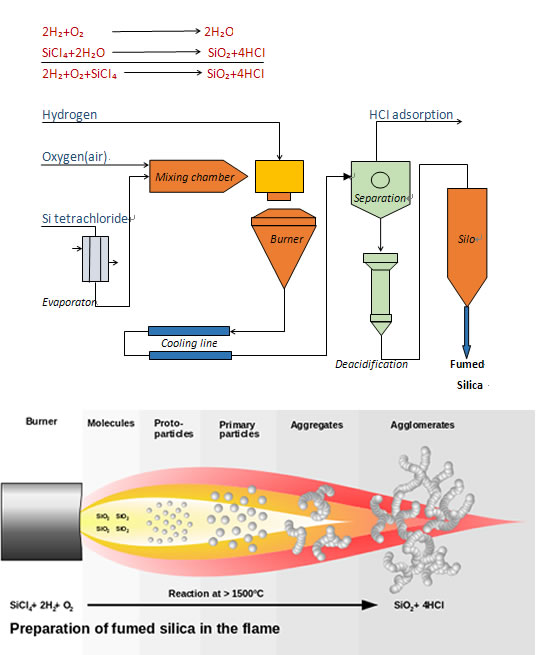

HJSIL® Fumed Silica adopts advanced Vapor Phase method. The process includes seven courses: raw material disposal, pyrohydrolysis, agglomeration, gas-solids Separation, deacidification, Packing, waste treatment. The average diameter of spherical primary particle varies from 7to 40nm by using different reaction condition during flame hydrolysis. There are various HJSIL grade with BET surface area between 90 and 380. HJSIL® Fumed Silica is divided into two groups according to surface chemistry.

. Hydrophilic Fumed Silica: This kind of fumed silica is produced during the normal flame hydrolysis of silane.

. Hydrophobic Fumed Silica: This kind of fumed silica is produced by reacting hydrophilic silica with organosilanes such as dimethyldichlorosilane. Hydrophobic fumed silica is used in critical applications where resistance to water absorption is important.